Browns Lane

Houses now cover the site where once some of the most famous Jaguar models were designed and built – Browns Lane in Coventry.

William Lyons moved the fledgling Swallow Sidecar factory from Blackpool to Coventry to be near the heart of the British motor industry. Based at Foleshill, Swallow and SS Cars grew in stature and soon the brand name became a byword for stylish, comfortable luxury cars at an affordable price. World War Two brought car production to a halt and SS Cars turned their attention to war production. However, during the war years William Lyons planned for the future, which included a new engine designed in-house that would be ready for production by the cessation of the war.

Shadow Factories

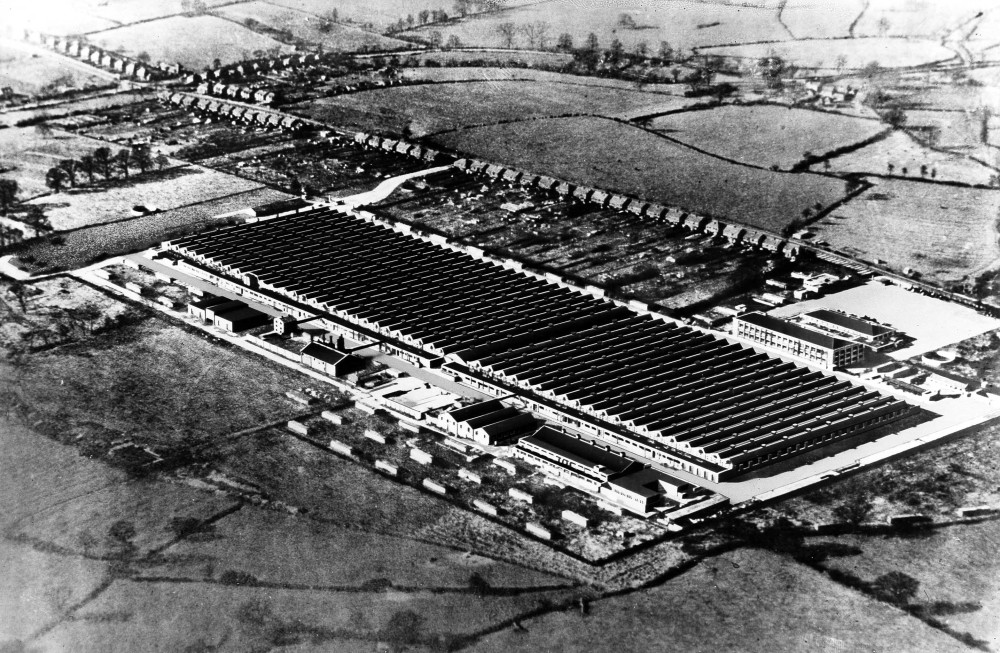

In 1936, faced with a real possibility of war the British Government pledged a large sum of money into building ‘shadow’ factories to produce armaments. These factories, many based in the Midlands, were built quickly to supplement established concerns already producing military matériels and ‘shadowed’ the main aircraft engine manufacturers. Factories built in the Midlands were managed by the motor manufacturers in the area. By the end of 1937 these factories were operational and under the control of the Ministry of Aircraft Production. Daimler had two such shadow plants, Number 1 was on their main Radford factory site and the other, Number 2 Shadow Factory, was located on what had been open countryside by the village of Allesley near Coventry.

Number 2 shadow factory was built on 6.2 acres (2.5 hectares) of land and work commenced a week after the required official documents had been signed. The first building to be completed was an assembly shop of around 308,200 sq ft (28,632 sq m), with attached offices, test area and a canteen. Quite soon afterwards the buildings were expanded and the assembly area was increased to 844,936 sq ft (78,497 sq m) with additional office space and an accommodation section.

Much of the design for the layout of the factory buildings was planned by George Hally, who would later become Managing Director of Daimler in February 1941. By the time war was declared in September 1939 the facility was 1,530 ft (466 m) long, 400 ft (122 m) wide and 20 ft (6m) high; this allowed overhead gantries to be installed.

The principal behind the shadow factories was to enable the manufacture of parts for aircraft engines, Bristol Hercules in the case of Daimler, and then for the parts to be shipped to Bristol Engines at Filton or Austin at Longbridge for assembly into complete engines. However, a decision was made to allow Daimler and Standard to manufacture complete engines.

When Coventry was severely bombed on 14 November 1940, many factories in or near the city centre were put out of action or badly damaged; this included the Radford plant, but it was the subsequent raid on 8 April 1941 that almost put paid to Daimler at Radford.

Half of the factory was wrecked, all the stores, erecting shops, tool room and spare parts department were wiped out. The drawing offices, planning office and works office were burned to the ground; the general offices were set on fire and all the ledgers, wages books, cost books and most of the sales records were destroyed. Later it was found that over 150 high explosive and numerous incendiary bombs had fallen on that factory that night. Shadow factory No 2 was out of the danger zone and was not affected.

Some work and personnel from Daimler’s Radford plant were transferred to Browns Lane. A number of those Daimler employees who had been made homeless as a result of the bombing were given shelter in the accommodation block.

When the war ended in 1945 Daimler continued to operate from Browns Lane, as there appeared to be no hurry to vacate the premises, it also gave them time to rebuild the damaged Radford factory. Also, still operating from the site were the General Electric Company (GEC) and the General Post Office (GPO), both of whom had office blocks within the Browns Lane complex. Government contracts for engines were cancelled and Browns Lane became the centre for the continuing production of the Daimler armoured and scout cars for the British Army.

Meanwhile, SS Cars, now renamed Jaguar Cars (April 1945), at Foleshill were busy with their post-war products and by 1949 had put the Mark V saloon, the XK120 and XK engine into production. They were expanding and, with the export success of the XK120, found they required additional space. None was to be had at Foleshill so William Lyons looked around for a suitable alternative.

Leasing a Factory

By 1950 Daimler had moved most of their work and personnel back to Radford and the Browns Lane plant was under-used. Lyons contacted (Sir) Archibald Rowlands at the Ministry of Supply, who administered the Shadow Factories, and asked about leasing the former Daimler site. They were delighted to find a tenant and a fee of £30,000 was agreed for a lease of five years. Lyons also arranged with Rowlands that if any other Government factories were let on more favourable terms, these terms would also be applied to the Browns Lane site.

Preparations to move Jaguar from Foleshill to Browns Lane were made and a local Coventry firm, Ernest Holmes, was chosen to co-ordinate the undertaking. A convoy of lorries was assembled and to keep disruption to a minimum each section was transported at weekends. Jaguar Cars moved from Foleshill to their new home, which would become closely associated with the marque.

Jaguar now had a large modern factory and to make certain that it would be used to capacity and also generate additional revenue, Lyons wrote to Rowlands in December 1950 asking if there were any military vehicle or engine contracts available. This bore fruit the following year when the Ministry of Supply issued a contract for the manufacture of Meteor tank engines.

The archive material does not make clear whether this contract was separate from or part of the Browns Lane lease agreement.

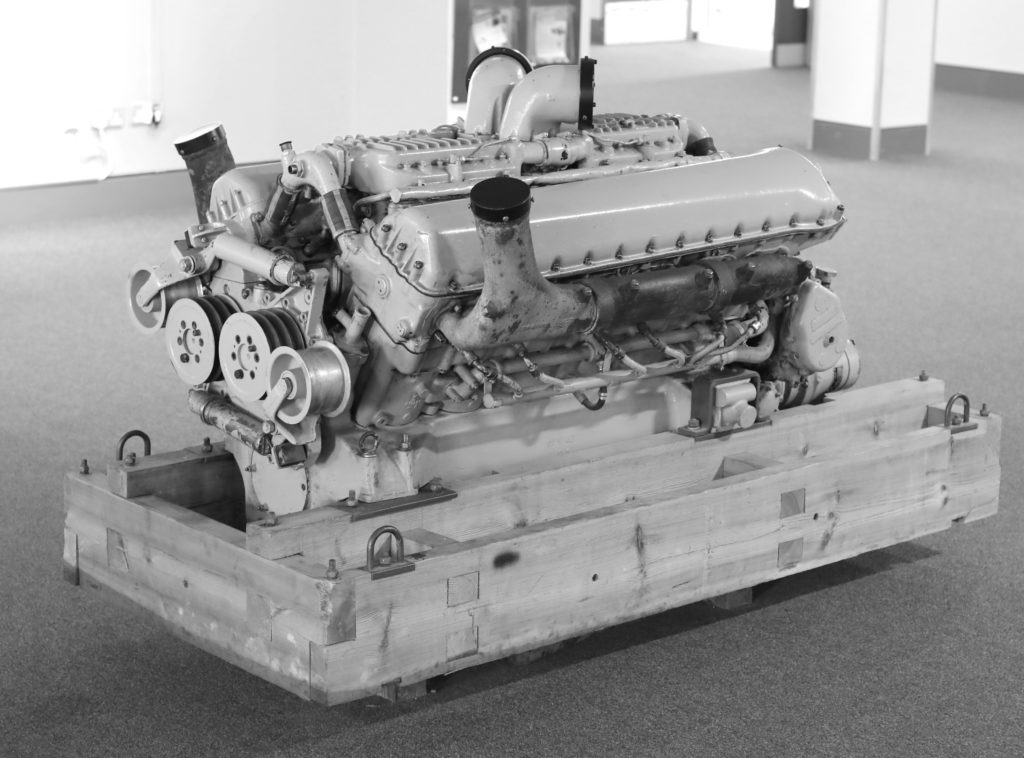

NB: The Meteor engine (pictured left) was adapted from the famous Rolls-Royce Merlin aircraft engine, for use in road-going vehicles.

The first department to leave Foleshill was the machine shop and by November 1950 the tool room and the road testing department had arrived at Browns Lane. Daimler was still in residence and moving out at a slow pace and it was not until November 1952 that Jaguar had completed the move to Browns Lane, the Experimental department was one of the last to be installed. Something else that had to be considered was the workforce – now over 3,000 strong – and how they could make the journey to the new site. Discussions with Coventry City Council resulted in bus routes being revised to enable workers, who lived near Foleshill, to get to Browns Lane without the need to change buses mid-journey. Some special buses were put on to take Jaguar workers to and from the new factory. To mark the move to Browns Lane, on 28 November, Jaguar hosted an event for dealers, distributors, suppliers and the press to view the site.

Jaguar was producing around 35 Meteor engines a week which, as Lyons noted, provided as much revenue as the car production. However, by 1952 car sales had increased dramatically and when the Ministry of Supply cancelled the contract for the Meteor engine at the end of 1952, the spare capacity was soon filled by XK120s and Mark VIIs.

At this time, Browns Lane housed body manufacture for the XK, a paint shop, machining and assembly of the XK engines and final assembly of the cars. Also located at Browns Lane were all the administration and other departments that had been at Foleshill. For the assembly lines at Browns Lane, Lyons purchased redundant equipment from the Standard Motor Company at Canley that otherwise would have been scrapped. In the paint shop, Jaguar replaced cellulose with synthetic paint, the first British specialist car maker to adopt this new type of paint. In the build ledgers the different types of paint which were being tried out are listed.

Production of cars increased and at a board meeting in July 1953, Lyons reported that 250 cars were being produced each week. Around 70 per cent were still being exported but the same meeting records that provision was being made to release more cars to the home market.

To show that Jaguar now occupied the site, a new office block was built on the west frontage of the factory, in sight of the main entrance gates on Browns Lane. William Lyons had his office on the first floor, as did all subsequent managing directors.

In 1955 the last wartime tenant, the General Electric Corporation, moved out of Browns Lane where it had occupied a building at the southern end of the site; the Jaguar design and engineering departments moved in. This building was associated with GEC and until the site closed in 2005 was always referred to as the ‘GEC Block’, even though that company had not been on the site for over fifty years.

Meanwhile, a new model had been designed and its method of construction was a total departure from the Jaguars that had so far been produced. As a monocoque the 2.4-litre small saloon had no chassis and £360,000 was invested in new tooling, with a further £300,000 allocated to expand the plant to accommodate the anticipated volume sales.

Additional staff were taken on to build the model and by the end of 1956 there were more than 4,000 on the pay-roll. The bodies for the 2.4 and later 3.4 models were made by Pressed Steel at Cowley and taken to Browns Lane where they were mated with the running gear, painted, trimmed and completed ready for despatch.

That year saw William Lyons created Knight Bachelor in the New Year Honours List for services to the British motor industry and exports. In March, HM The Queen and HRH Prince Philip visited Browns Lane and the office block was suitably decorated inside and out for the occasion.

This was to be the first of many visits by HM The Queen and other members of the Royal family to Browns Lane over the years.

Disaster and Rebuilding – the 1957 Fire

Browns Lane was in full production with new models being designed and the future looked good, but on the evening of 12 February 1957 a fire broke out in the tyre stores and swept through an area of over 200,000 sq ft (18,580 sq m), about a quarter of the factory complex.

The fire affected the sawmill, the test department, material stores, parts of the assembly line and the despatch area, where a large quantity of various Jaguar models were stored; the few workers still on site saved some of these cars by driving or pushing them out into the car parks but several hundred cars were totally destroyed.

Sir William took the opportunity to assure dealers and distributors in Britain and abroad that Jaguar production would continue, at a lower rate, until the damaged factory could be rebuilt. As soon as they were allowed back onto the site the workforce, including Lyons and other members of management, set about clearing the debris.

Jaguar was supported by its suppliers and by rival members of the British motor industry such as Rootes, Daimler and Armstrong-Siddeley (among others) who proffered their condolences and real offers of help. Dunlop, who had taken over the Foleshill factory, made space to accommodate some homeless departments from Browns Lane.

Jaguar was back in production almost immediately and by July 1957 the rebuilding of the damaged plant had been completed and an extension of the assembly line to the north of the site was started. The following year, Sir William concluded negotiations to purchase outright the Browns Lane site for £1.25 million.

However, as Jaguar sales continued to rise so too did the need for additional space and to address this issue, in 1960, Lyons purchased the ailing Daimler Car Company and in doing so gained their large factory at Radford. Some Daimler production was moved to Browns Lane and Radford became the main assembly plant for Jaguar engines.

In 1960 Jaguar production, for the first time, exceeded 20,000 cars, most were Mark II saloons, and the following year Lyons announced the E-type, of which little needs to be said here. The Mark X saloon was also launched in 1961.

British Leyland

Jaguar continued to grow and both plants were working to capacity; the XJ6 was released in 1968 and quickly became a world-beater in terms of quality and value for money. Jaguar had by now added Coventry-Climax and Guy Motors to the group and turnover had increased accordingly. However, Jaguar was still a small player in the world of automobiles and to safeguard his company, Lyons formed an alliance with Sir George Harriman and the British Motor Corporation (BMC), to create the British Motor Holdings Group.

Sadly this did not work out, Harriman retired through ill health and BMH was merged with Leyland to form the British Leyland Motor Corporation (BLMC or BL) of which much has been written. Lyons retired in 1972 and with a re-organisation of BLMC, Jaguar was just another marque with Leyland Cars, and Browns Lane became ‘Leyland Cars Large Car Assembly Plant No.2’.

The sorry saga of Jaguar in the time of British Leyland is documented elsewhere, but suffice to say that there was very little change at Browns Lane in the way of new plant and investment. BL did consider expansion plans by buying land adjacent to the factory but this came to nothing and there was even talk about moving Jaguar out of the Coventry area using government finance schemes.

Meanwhile, Jaguar’s second in-house-designed engine, the V12, was announced and built at Radford; car production continued at Browns Lane and when production of the E type came to an end in June 1974, body manufacture ceased at Browns Lane, which now became purely an assembly plant. The bodies came exclusively from Castle Bromwich; that same year Jaguar produced almost 36,000 cars, a record at the time.

Michael Edwardes (later Sir Michael) was appointed to head British Leyland in November 1977 and the following year Jaguar was made a separate entity with Robert (Bob) Knight as Managing Director reporting to William Thompson head of the new Jaguar-Rover-Triumph Division of BL. However, in a year Jaguar-Rover-Triumph had been wound up and by 1980 Jaguar was independent within BL with John (now Sir John) Egan appointed as Managing Director.

Egan set about making Jaguar a great name once more and was able to restore some of its lost lustre and gradually the Company was reshaped. In 1983 Jaguar bought back the Browns Lane plant from BL for £3.5 million, later the Radford factory was acquired for one million pounds and finally Castle Bromwich (from Pressed Steel Fisher) for £7 million. The dealer network was also addressed and a set of new standards was introduced.

Egan then led Jaguar through a successful privatisation by an issue of shares on the London Stock Exchange on 3 August 1984 and by 1986 was in a position to introduce a new model, the XJ40. This model, shown in Paris, along with the XJS, restored Jaguar’s place in the automotive scene and in 1988, for the first time, Jaguar produced over 50,000 cars, all from Browns Lane. A few changes were made at Browns Lane such as a computerised body store at the northern end of the assembly hall and a new road around the site.

In 1989 the Ford Motor Company purchased Jaguar Cars and started a new era of development at Browns Lane. The first major change was a new entrance being created in Coundon Wedge Drive which allowed easier access to the site and stopped heavy lorry traffic through the residential Browns Lane.

In the summer of 1993, Ford-Jaguar installed a much needed new assembly line with overhead cradles making production more efficient.

The End for Browns Lane

In 1998 a new Museum block was built and opened, just inside the old Browns Lane entrance, for the Jaguar Daimler Heritage Trust (JDHT), to house the archives of the Company and to display some of the vehicles in the collection.

For 2000 the old administration block was given a major refurbishment and extended; a Jaguar Gallery was created at one end of the building to showcase the Company’s activities to the many visitors who continued to come to Browns Lane to see where the famous cars were made.

Ford continued their investment in Jaguar and by 2001 there were three factories – Browns Lane, Castle Bromwich and Halewood – producing Jaguar models.

However, with no body production at Browns Lane and with no possibility of expanding the site, the decision to close it was made and on 1 July 2005 the last of 1,447,677 cars built at Browns Lane came off the line. This was an XJ saloon (registered XJ05 JAG) which was handed over to the JDHT.

For some time the Browns Lane site remained dormant until sold for housing and light industrial use. However, though there are no visible signs that Jaguar were once located at Browns Lane, many owners and enthusiasts still make the journey to what was once the home of Jaguar Cars.

Postscript: The main site is now called Lyons Park and is accessed via Sayer Way; the housing estate has been named Swallow’s Nest; some of the roads have been named after various Swallow-Jaguar personnel such as Lyons, Heynes, Fenton, Walmsley and others. While this may not mean anything to the non-Swallow-SS-Jaguar person, at least some of the names associated with the marque are remembered.

Authors: François Prins with additional information from Tony Merrygold

© Text and Images – Jaguar Cars Ltd and Jaguar Daimler Heritage Trust